Applications Insight: 3D Printed PEEK Shoe Mold

Datang Xinxin Rubber & Plastic Co. Ltd was established in 1989 and located In Nanhai District Foshan City, Guangdong. The factory covers an area of 60,000 square meters and has more than 500 employees. They are specialized in production of various EPR/EVA/ Rubber sole materials, sports equipment and leisure products, which meet the international environment ROHS standards, and sell well at both domestic and oversea market. At present, the company produces 5 million pairs per year, and earn up to 100 million yuan per year.

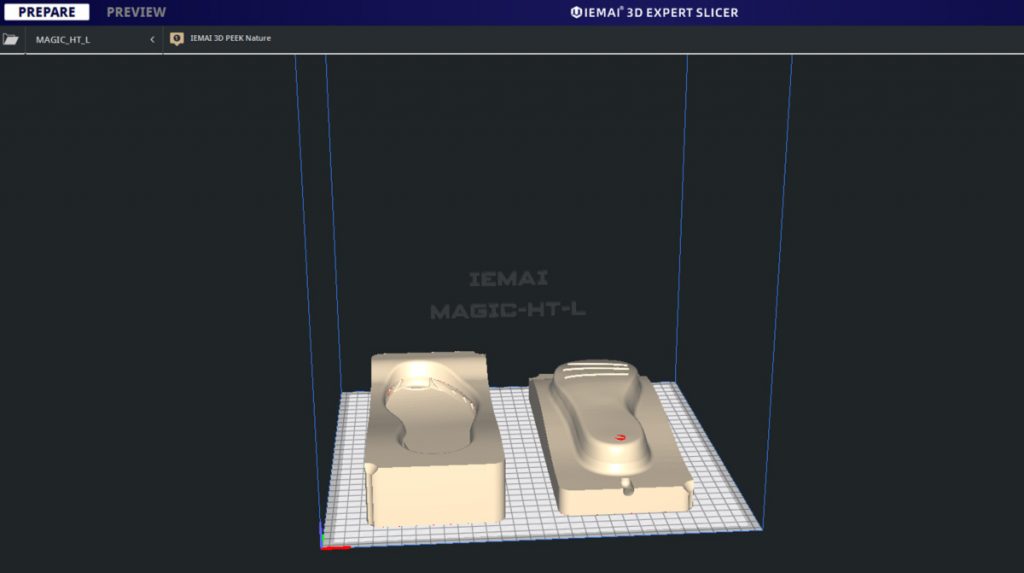

Therefore, 3D printing PEEK mold only needs to ensure that it can be used three times, that means, this method can greatly improve the efficiency of mold development. By using 3D printed mold, mold development projects can be quickly realized to improve R&D efficiency and meet all high temperature and high-pressure criteria. IEMAI 3D MAGIC-HT-L 3D printer can achieve a layer resolution of 0.05-0.3 mm and it performs very well when printing large-size PEEK molds. It is the best molding effect among several companies in comparison. There is no wrapping happening when printing, thus, Datang Xinxin Rubber and Plastic Pte Ltd choose this model to produce PEEK material development molds.

The project manager of Datang Xinxin Rubber and Plastic Co. Ltd said, “Using IEMAI 3D printing solutions, we greatly shorten the time required to R&D mold and verification. We believe that 3D printing technology can change the entire industry in the future.